Moving from “Command and Control” to “Design and Do”

One mistake that we humans make is that we think we have time. Well, we don’t. Not really. For example, we’ve known for at least 30 years that our organizations – built with an industrial age logic, grounded in linear thinking – do not learn and adapt quickly in complex, dynamic environments. We know this. But we have had trouble doing anything about it.

In the 1990s, two Stanford business professors even wrote a book about how we get stuck. Jeffrey Pfeiffer and Bob Sutton titled their book, The Knowing Doing Gap.

It’s understandable. Change is hard. We like the safety of old habits. Change is also tiring. It wears us out. And change can also trigger our fears of the unknown. Instead of confronting these fears, we can easily occupy our time with what’s familiar. We develop excuses for not acting.

But here’s the rub. Change is unavoidable, and it’s accelerating.

Why it matters: the internet has changed everything

In 1992, I was sitting in a restaurant in Singapore. My lunch companion was the chief technology officer of a early Internet start-up, one of my client companies. A PhD physicist, he had recently left his position in one of the US federal labs.

Our lunchtime conversation changed my life’s direction. Here’s how.

As we were exploring the impacts of globalization, Jonathan alerted me to an important change on the horizon: the launch of the commercial Internet. “Internet is our first interactive mass medium. We don’t really know what that means, but it will change everything.”

Wise words.

Thirty years ago.

Now, we know it’s true.

Our traditional management frameworks don’t work well in dynamic environments

I told Jonathan that I didn’t think we were prepared to manage organizations and networks in this New Age. He agreed. And then he passed on some valuable guidance.

“Learn about open-source software development. Understand how a group of people can come together in an open, loosely connected networks and do complex work together. If you can figure that out, you have a path forward.”

In short, Jonathan was telling me, “Stop trying to address new challenges with old tools. Design new tools and frameworks based on open networks, not closed hierarchies.”

That conversation kicked off a decade-long exploration to find a better way to address our complex challenges. (Strategic Doing was born from these experiments.)

Dig deeper: Design & Do management

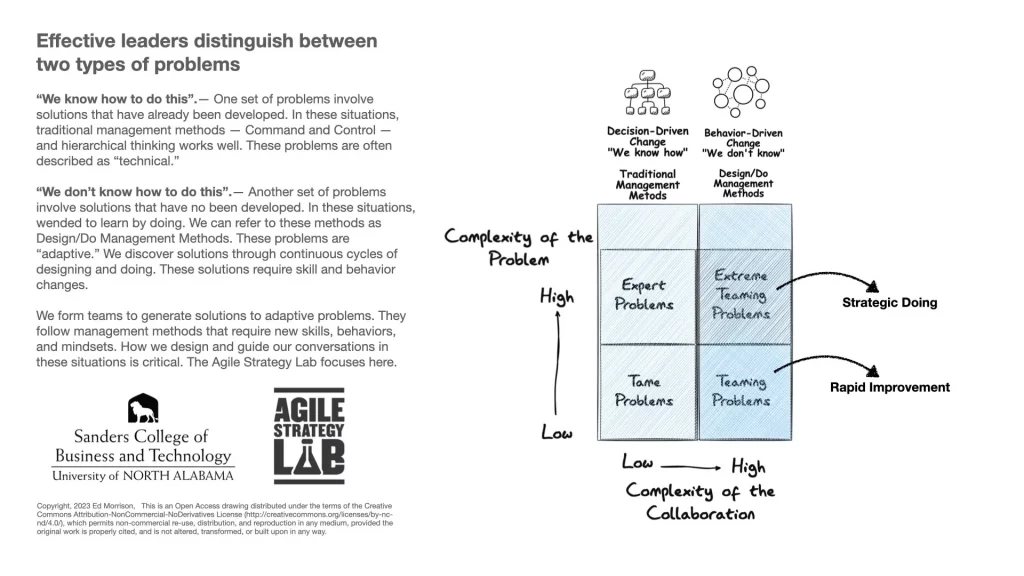

My friend and colleague, Doug Smith, a former McKinsey partner and head of their global organizational performance practice, puts our management challenge this way. When we confront a new problem, we either know a solution or we don’t. If we know the solution, then traditional management practices, grounded in hierarchies, work well.

But increasingly, we don’t know the solutions to the problems we confront.

Indeed, that’s the crux of our dilemma. The world around us is moving faster…thanks to the Internet. And it’s presenting us with problems we have never confronted before.

We need new management skills, behaviors, frameworks, and routines. Simple rules of thumb (heuristics) to address complexity. These are discovery-driven approaches to new solutions. A never-ending process of experimentation, learning, and adaptation.

It’s Design and Do Management.

The essence of Design & Do management: moving from individuals and tasks to teams and collaboration

In 1911, Frederick Winslow Taylor, a mechanical engineer, wrote a book that set the cornerstone of for our traditional management practices. (In 2001, the Academy of Management voted the book the most influential in the 20th century.) Taylor’s principles of scientific management focus on how managers can organize work for everyone’s benefit by following the logical disciplines of an engineer.

He set forth principles for designing an organization like a precision watch. Convinced that organizations could be far more productive, he focused on the precise definition of everyone’s task. Taylor’s approach to management worked remarkably well when we need to organize a complicated process to produce a known solution (building an automobile, producing a ton of steel).

Design and Do Management is different. It focuses on teams, collaboration, and continuous learning.

The origin of Design & Do management in Japan

My initial exposure to Design and Do management practices came in Hiroshima, Japan in 1984. I was part of the first U.S. consulting team to examine Japanese auto manufacturing in depth. Our clients, the Ford Motor Company and the UAW, wanted the answer to a simple question: how can Mazda manufacture essentially the same car as Ford but at a significantly lower cost?

My job was to focus on the differences in the manufacture of the engine and transmission. I won’t go into what I learned in depth, but I came away with a fundamental understanding that the Japanese were manufacturing the same car with a completely different production model. Their approach leveraged networks to accelerate learning and collaboration. (Within Ford’s command and control approach we found many hidden sources of inefficiency.)

Most managers have come to know this approach as the Toyota Way or lean production, pioneered by the Toyota Motor Company.

Design & Do management: new skills and behavior

Design and Do Management is a discovery-driven process. It generates solutions to problems when we don’t know what to do. The process lifts our focus from individuals and tasks to teams and collaboration.

We rapidly alternate our focus from “the system and performance outcomes” (viewing from the balcony) to “projects and next steps” (viewing from the dance floor). Practitioners develop an agile mindset capable of switching perspectives quickly. Back and forth.

In the Agile Strategy Lab, we have developed and tested two Design and Do Management frameworks for two different situations.

Strategic Doing works well when confronting wicked problems. We don’t have the solution, but it is also very difficult to define the challenge. Rather than focus too much on underlying causes (which are, by definition, difficult to untangle), we focus our attention on the future state: the outcomes we would like to achieve. Companies can use Strategic Doing to accelerate collaborations, open innovation, and the development of ecosystems.

Rapid Improvement works well to redesign existing systems. We apply team-based, lean disciplines to dramatically improve performance. Often our existing systems represent incremental changes that accumulate over time. These routines become shared habits that often create an immunity to change. (“We’ve always done it this way.”) However, when we think more rigorously about improving performance from a systems perspective, we can identify wasted time and unnecessary steps. Through continuous experimentation we can dramatically improve our existing systems.